The ceramic kiln change process is a unique ceramic process that creates unpredictable color and texture effects through chemical changes in the glaze during high-temperature firing. This process has a long history in ceramic making, and with the advancement of modern technology, the application scope of the Kiln Change process is also expanding. Its uniqueness lies in that each Kiln Change work is unique, which is why many ceramic enthusiasts and collectors favor it.

What is Kiln Change?

Kiln Change refers to the complex chemical reaction of glazes at high temperatures during the ceramic firing process, forming natural, irregular color and texture effects. This process is usually uncontrollable because many factors, such as temperature, environment (oxidation or reduction) and the structure of the kiln, will affect the final result. The origin of Kiln Change can be traced back to ancient Chinese ceramic-making technology, and modern ceramic artists have carried forward this process through continuous experimentation and improvement.

Technical details of the Kiln Change process

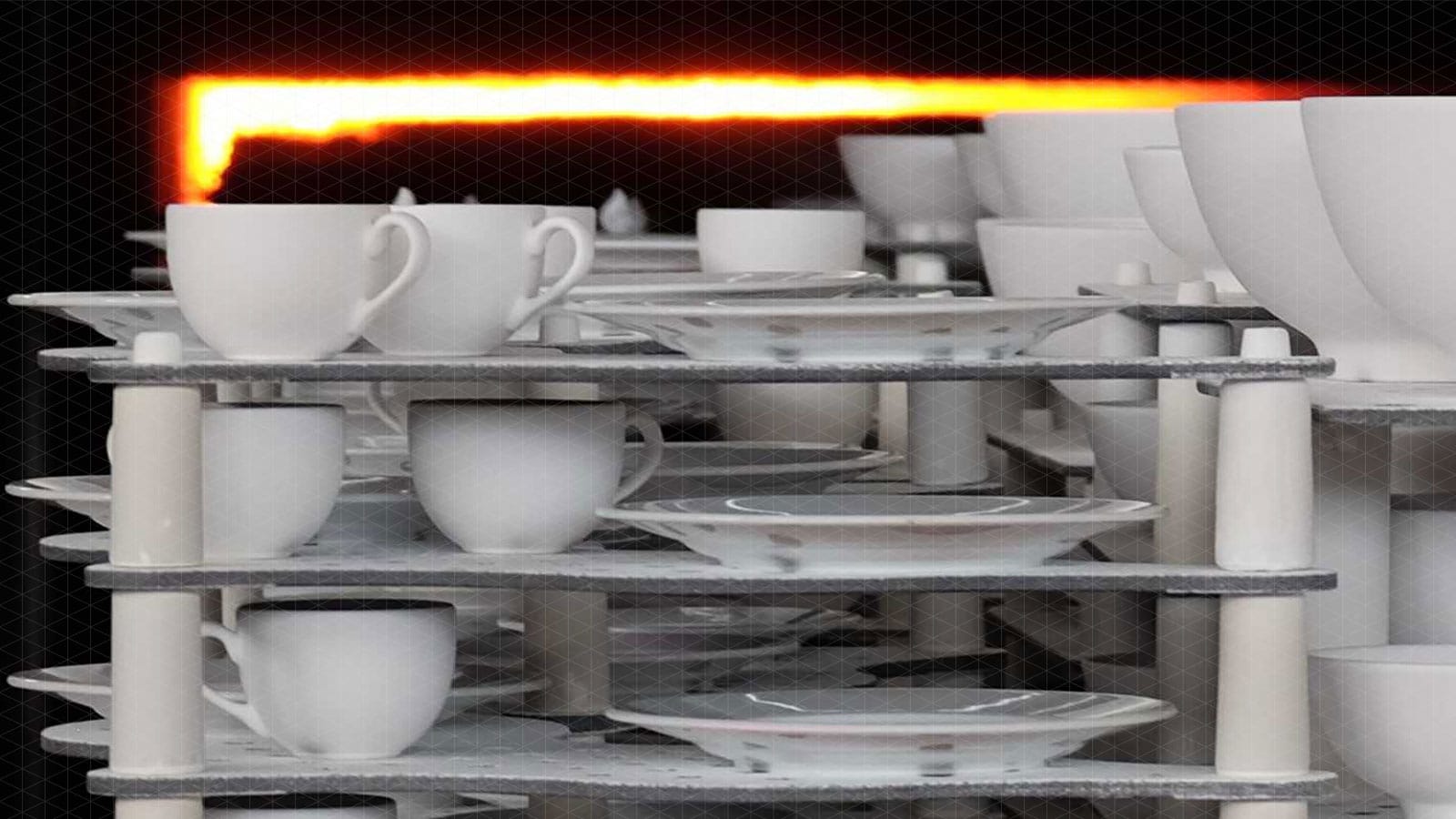

During the Kiln Change process, the chemical composition of the glaze changes at high temperatures, resulting in unique colors and textures. Different glaze combinations, firing temperatures, and kiln environments all affect the final effect. For example, an oxidizing atmosphere produces bright colors, while a reducing atmosphere makes the glaze deep and textured.

Controlling the firing environment is key to the Kiln Change process, and changes in the kiln’s temperature and internal atmosphere often determine the color and texture of the final work. However, although modern technology allows us to better control the firing process, Kiln Change still retains its uncertainty, which is also its charm artist cannot fully predict the final effect of each work.

How ceramic factories apply the Kiln Change process

In modern ceramic factories, the Kiln Change process is widely used in mass production and high-end customized production. Although Kiln Change has a certain degree of uncontrollability, many factories combine this traditional process with modern production technology through innovative technology and precision equipment to make it more controllable in mass production.

The biggest challenge faced by factories when applying the Kiln Change process in mass production is how to ensure production efficiency and consistency while ensuring that each piece is unique. To this end, many ceramic factories seek a balance by adjusting the kiln atmosphere, temperature control and glaze formula so that the Kiln Change process can create unique effects while maintaining the operability of commercial production.

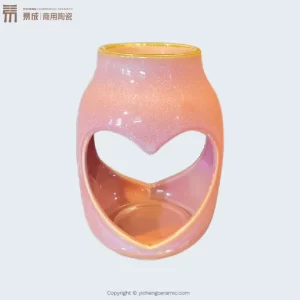

When the ceramic manufacturer provides customers with customized Kiln Change ceramic products, it will adjust the firing process according to the customer’s design requirements to create unique ceramic products for them. Common Kiln Change ceramic products include ceramic tableware and candle jars.

Application of Kiln Change technology in tableware

Kiln Change technology is widely used in tableware production. Through this technology, tableware is not only practical but also has extremely high artistic value. The natural color changes and unique textures make each Kiln Change tableware like a work of art, greatly enhancing the beauty of the table.

In recent years, Kiln Change tableware has become increasingly popular in the high-end market and at home. Whether it is used for formal table settings or daily use, Kiln Change tableware can add a unique style to the table. Especially in modern design, the natural color and texture of Kiln Change complement the simple style and are deeply loved by young consumers.

Ceramics manufacturer combines Kiln Change technology with modern elements to create a tableware series that combines traditional charm and modern fashion. This innovation makes our Kiln Change tableware not only popular in the domestic market, but also exported to all parts of the world, becoming a popular product in the international market.

How to Appreciate and Select Kiln Change Ceramics?

There are several key points to note when selecting and appreciating Kiln Change ceramics. The first is the color change. Kiln Change works are usually rich and varied in color, with a gradient effect. The second is the texture of the glaze. A good Kiln Change work should have a delicate glaze and natural texture. In addition, the overall design and the sense of balance of the work are also important factors in evaluating Kiln Change ceramics.

When you choose Kiln Change tableware or other ceramic products, you can choose according to your personal style and usage scenarios. If it is for formal occasions, you can choose works with more low-key colors and delicate textures; for daily home decoration, you can choose Kiln Change ceramics with richer and more diverse colors.

Conclusion

The Kiln Change process perfectly combines traditional ceramic production technology with modern artistic expression to create an unrepeatable beauty. Its uniqueness lies not only in the uniqueness of each piece but also in the artistic effect it creates through natural changes.

Whether it is factory mass production or handmade by artists, the Kiln Change process always maintains its unique charm. In the future, with the further development of technology, the application prospects of the Kiln Change process will be broader.

The Chaozhou Ceramic Manufacturers Association has skilled manufacturers capable of producing kiln-formed ceramics. With the expertise in the process of changing the kilns, the manufacturers are capable of producing unique and high-value ceramic products that have been recognized both nationally and internationally. It continues to encourage innovation and excellence within the industry, having supported its members to seek out new opportunities in ceramic art and design.